The pharmaceutical industry is one of the most advanced sectors when it comes to technological innovation. The need for efficiency, safety, and regulatory compliance drives constant improvements in manufacturing processes, with pharmaceutical equipment playing a crucial role. As we move toward 2024 and beyond, several technologies are transforming the way pharmaceutical equipment is designed, manufactured, and operated.

In this article, we will explore the key innovative technologies reshaping pharmaceutical equipment, including automation, artificial intelligence (AI), the Internet of Things (IoT), 3D printing, blockchain, sustainable manufacturing, and digital twins. We’ll also dive into a real-world case study and answer frequently asked questions to provide a complete view of this exciting topic.

1. The Rise of Automation in Pharmaceutical Manufacturing

Automation in pharmaceutical manufacturing refers to the use of machines and control systems to operate processes that would otherwise require human intervention. The shift toward automation is largely driven by the need to improve efficiency, reduce human error, and cut operational costs.

- Global Pharmaceutical Automation Market Growth: The pharmaceutical automation market is expected to reach USD 22.4 billion by 2023, with a projected compound annual growth rate (CAGR) of 8.2% from 2024 to 2030.

How Automation Benefits the Industry

Automation allows for higher throughput, precision, and consistency. Machines can handle repetitive tasks such as tablet filling, blister packing, and labeling with minimal human involvement. Automated systems also enhance quality control by ensuring that every product meets the required standards.

For example, robotic arms are increasingly being used in tablet packaging and filling processes, enabling faster production cycles and reducing the risk of contamination.

Key Advantages of Automation

- Improved Efficiency: Automated systems can operate 24/7, leading to higher production rates.

- Reduced Human Error: By removing human intervention from critical processes, automation ensures consistent product quality.

- Cost Reduction: Automation lowers labor costs and reduces the risk of costly errors or product recalls.

2. The Role of Artificial Intelligence (AI) in Equipment Optimization

AI is playing a pivotal role in optimizing pharmaceutical manufacturing equipment. AI technologies, such as machine learning and deep learning, can process vast amounts of data and make decisions that improve efficiency and production quality.

- Market Impact: AI is projected to reduce drug manufacturing costs by as much as 30% by optimizing processes, predicting maintenance needs, and enhancing product design.

How AI Enhances Pharmaceutical Equipment

AI systems can predict equipment failures before they occur by analyzing real-time data from sensors and other sources. This predictive maintenance minimizes downtime and reduces costs associated with unplanned repairs.

AI-driven analytics also improve equipment design by identifying inefficiencies in the manufacturing process and suggesting improvements. In some cases, AI has been used to enhance the design of tablet compression machines, leading to a 20% reduction in downtime and higher overall equipment efficiency.

Key Benefits of AI in Pharmaceutical Equipment

- Predictive Maintenance: AI can predict when equipment is likely to fail and schedule maintenance before issues arise, reducing costly downtime.

- Optimized Processes: Machine learning algorithms can analyze large datasets to optimize manufacturing processes and improve overall productivity.

- Real-Time Monitoring: AI-powered monitoring systems can detect issues as they arise and recommend immediate corrective actions.

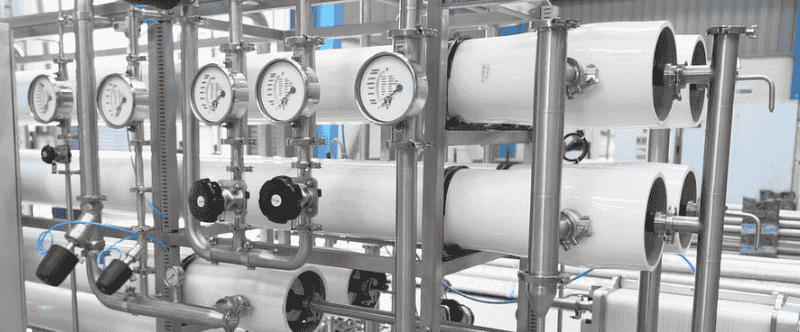

3. Internet of Things (IoT) and the Future of Connected Pharmaceutical Equipment

The Internet of Things (IoT) refers to the network of devices that are connected to the internet, allowing for the real-time exchange of data. In pharmaceutical manufacturing, IoT technologies are being used to connect equipment, monitor performance, and ensure compliance with stringent regulatory standards.

- Market Overview: The global IoT in healthcare market is expected to reach USD 72.5 billion by 2023, with a 24.5% CAGR until 2030.

IoT-Enabled Pharmaceutical Equipment

In a pharmaceutical plant, IoT sensors can monitor everything from temperature and humidity levels to the pressure in manufacturing lines. These sensors send data to centralized systems, which can trigger alarms or automated actions if certain thresholds are exceeded.

For example, in sterile environments, IoT sensors ensure that the conditions are optimal for drug production. If humidity levels or temperature fluctuate outside the acceptable range, the system can adjust the environment or notify operators for manual intervention.

Benefits of IoT in Pharmaceutical Manufacturing

- Improved Compliance: IoT devices enable continuous monitoring, ensuring that pharmaceutical equipment remains compliant with health and safety regulations.

- Real-Time Data: IoT allows manufacturers to monitor equipment and processes in real-time, providing immediate insights into performance and issues.

- Better Traceability: IoT improves traceability in the production process, which is essential for quality control and product recalls.

4. 3D Printing: Revolutionizing Pharmaceutical Equipment and Drug Manufacturing

3D printing is making waves in the pharmaceutical industry, not only for creating custom drug doses but also for manufacturing pharmaceutical equipment parts. This technology allows for rapid prototyping, precision manufacturing, and on-demand production, reducing waste and increasing flexibility in design.

- Growth in 3D Printing: The global 3D printing market in healthcare is expected to grow from USD 1.5 billion in 2023 to USD 6.4 billion by 2030, at a CAGR of 22.5%.

Applications of 3D Printing in Pharmaceutical Equipment

3D printing allows for the creation of highly specialized equipment components that are tailored to specific needs. For example, customized tablet presses and unique dosing systems can be produced in-house, cutting costs and reducing lead times.

Additionally, 3D printing is used to develop personalized drug doses for patients. By creating drugs with specific dosages and release profiles, manufacturers can better address the needs of individual patients, improving therapeutic outcomes.

Key Advantages of 3D Printing

- Customization: 3D printing allows manufacturers to produce custom equipment parts and personalized drugs, meeting specific patient needs.

- Reduced Waste: Since parts are printed on-demand, 3D printing minimizes material waste compared to traditional manufacturing methods.

- Rapid Prototyping: Designers can create prototypes quickly, allowing for faster testing and refinement of new equipment designs.

5. Blockchain Technology for Enhanced Drug Traceability and Compliance

Blockchain technology is widely recognized for its ability to provide secure, transparent, and immutable data. In pharmaceutical manufacturing, blockchain is being leveraged to enhance traceability and compliance by securely tracking drugs throughout the supply chain.

- Blockchain Market Overview: The blockchain in pharmaceutical market is projected to reach USD 1.2 billion by 2028, growing at a 20% CAGR.

How Blockchain Improves Pharmaceutical Equipment

Blockchain’s secure ledger system ensures that every transaction related to the production, distribution, and storage of pharmaceutical products is accurately recorded. This is particularly important for preventing counterfeit drugs from entering the supply chain.

For example, pharmaceutical companies use blockchain to track and authenticate vaccines, ensuring that each batch is genuine and meets quality standards.

Benefits of Blockchain in Pharmaceutical Manufacturing

- Enhanced Security: Blockchain ensures that all data related to drug production is tamper-proof and securely stored.

- Supply Chain Transparency: Blockchain allows for full visibility into the supply chain, which is crucial for preventing fraud and ensuring product authenticity.

- Regulatory Compliance: Blockchain helps pharmaceutical manufacturers comply with industry regulations by ensuring data integrity and providing a clear audit trail.

6. Sustainable Manufacturing Technologies in Pharmaceutical Equipment

Sustainability is becoming increasingly important in pharmaceutical manufacturing, not only to reduce environmental impact but also to comply with growing regulatory pressures. Sustainable technologies in pharmaceutical equipment manufacturing focus on energy efficiency, waste reduction, and resource conservation.

- Sustainability in the Industry: Pharmaceutical companies could save over USD 1 billion annually by implementing sustainable practices in equipment manufacturing.

How Sustainable Technologies Benefit the Industry

Energy-efficient machinery, the use of renewable energy sources, and the reduction of waste through closed-loop systems are just a few examples of sustainable practices in pharmaceutical manufacturing. These practices not only reduce environmental impact but also lower operational costs.

For instance, solar-powered production lines and biodegradable materials in packaging are becoming more prevalent, helping pharmaceutical companies meet their sustainability goals.

7. The Impact of Digital Twins on Pharmaceutical Equipment Design and Operation

Digital twin technology involves creating a virtual model of physical assets, such as pharmaceutical manufacturing equipment, that can be used for simulation, monitoring, and optimization. This technology is increasingly being applied in the pharmaceutical sector to enhance design and operational efficiency.

- Market Growth: The digital twin market is expected to grow from USD 5.2 billion in 2023 to USD 31.8 billion by 2030, at a 31.7% CAGR.

How Digital Twins Are Used in Pharmaceutical Manufacturing

Digital twins allow manufacturers to simulate equipment performance under different conditions, identifying potential issues before they occur. This results in optimized designs and reduced costs associated with equipment failure and maintenance.

For example, pharmaceutical companies are using digital twins to simulate tablet presses, optimizing parameters like speed and pressure for maximum efficiency.

Benefits of Digital Twin Technology

- Optimization: Digital twins allow for continuous improvement in equipment design and operation.

- Risk Reduction: Virtual simulations enable manufacturers to identify and address potential problems before they impact production.

- Cost Savings: By reducing the need for physical prototypes and optimizing equipment performance, digital twins help save both time and money.

Case Study: The Implementation of IoT and AI at Pfizer

Pfizer, one of the leading pharmaceutical companies globally, has successfully integrated IoT and AI technologies into their manufacturing operations. By installing IoT sensors throughout their production facilities, Pfizer monitors key parameters such as temperature and humidity in real-time. AI algorithms then analyze this data to predict when maintenance is needed, significantly reducing downtime.

As a result, Pfizer has seen a 20% increase in operational efficiency and has significantly reduced unplanned maintenance costs. This case highlights how integrating these innovative technologies can lead to a more efficient, cost-effective, and compliant manufacturing process.

FAQs

Q1: How does automation impact the pharmaceutical equipment industry?

Automation improves production speed, accuracy, and consistency. It reduces human error and allows manufacturers to produce more products with fewer resources.

Q2: What role does AI play in optimizing pharmaceutical equipment?

AI helps optimize equipment performance through predictive maintenance, real-time monitoring, and process optimization, ensuring that pharmaceutical production is efficient and cost-effective.

Q3: How is blockchain being used in pharmaceutical manufacturing?

Blockchain is used for tracking and verifying drug shipments, ensuring transparency and preventing counterfeit products from entering the supply chain.